Golden State Cider is the brainchild of Jolie Devoto and Hunter Wade. It has always been Jolie and Hunter’s mission to raise awareness and help revitalize California’s historic apple growing regions.

Devoto Gardens & Orchards was established in 1976, the year Stan and Susan Devoto moved “back to the land” from Berkeley buying a 20-acre orchard on Gold Ridge Road just west of Sebastopol. They started cultivating heirloom apples, cut flowers and micro-greens; the latter of which at the time was an innovative crop – a mix that included edible flowers – supplying Chez Panisse among other pioneering farm-to-table restaurants. They were also founding members of the nascent, Bay Area farmers’ market scene.

Years of heavy rain precluded any tractor work until March at the earliest. Stan and Susan’s daughter, Jolie, vividly recalls the tractor sometimes getting stuck in the muddy orchard during the middle of the night.

Just before bloom, apple trees come out of dormancy and display silver-tipped buds, soon to yield gorgeous multi-colored blossoms depending on the variety.

Lush springtime green. The overwintering cover crop prevents erosion and sets nitrogen in the soil.

A Gravenstein tree in full bloom

“Gravs” are the first to bloom, earliest to harvest. By design, Devoto Orchards are planted with over 100 different varieties of apples that yield a continuous, staggered harvest from early August to as late as November. The last variety to bloom/harvest is the Rome Beauty which is traditionally planted in zones prone to early frost.

Pink Pearl blossoms

Developed in 1944 by the plant breeder Albert Etter in Humboldt County, the Pink Pearl is one of the earliest to be harvested. Just like its bright pink blossom, the flesh of the fruit is tinged pink.

The bloom phase is the most vulnerable for apple trees, since if subjected to extended heavy rains honey bees are unavailable to pollinate their blossoms during the limited three-week bloom window. A bee has to visit every single blossom for it to become an apple.

There are two types of buds: ones which will yield a blossom and ones that will develop into leaves. There is a range of coloration for leaves, as well as blossoms, between different varietals.

Looking toward Guerneville in the distance

As the crow flies, Devoto Gardens & Orchards is about 13 miles from the Sonoma Coast. The orchard rows are planted north and south for maximum sunshine and airflow.

Fruit set

Transition from a pollinated bloom to the young fruit. One can observe the remains of the bloom at the exterior end. In five to six months these will be ready for harvest.

Cluster prior to thinning

Apples tend to form in clusters of five. The center apple, called the king bloom, will become the largest apple in any particular cluster. Clusters are thinned by hand down to one apple, affording an early opportunity to remove cosmetically-damaged fruit.

The remains of the curling brown blossoms which eventually detach

A more mature cluster before thinning

Clusters are thinned for size, flavor and ripeness. This labor-intensive, costly technique is employed for packing quality versus processing needs, i.e., apples going to market for eating as opposed to ones destined for the cannery or cidery.

Golden State Cider in cans

Jolie and her husband, Hunter Wade, joined Jolie’s parents on the farm in 2012 and made their first vintage of hard cider which they named Save The Gravenstein; inspired by the Apple Core, a Presidium of Slow Food Russian River. They started selling this first batch at farmers’ markets along with cut flowers and eating apples.

Hunter and Jolie rebranded their cider Golden State Cider in 2014 and moved from packaging in glass bottles to cans and kegs.

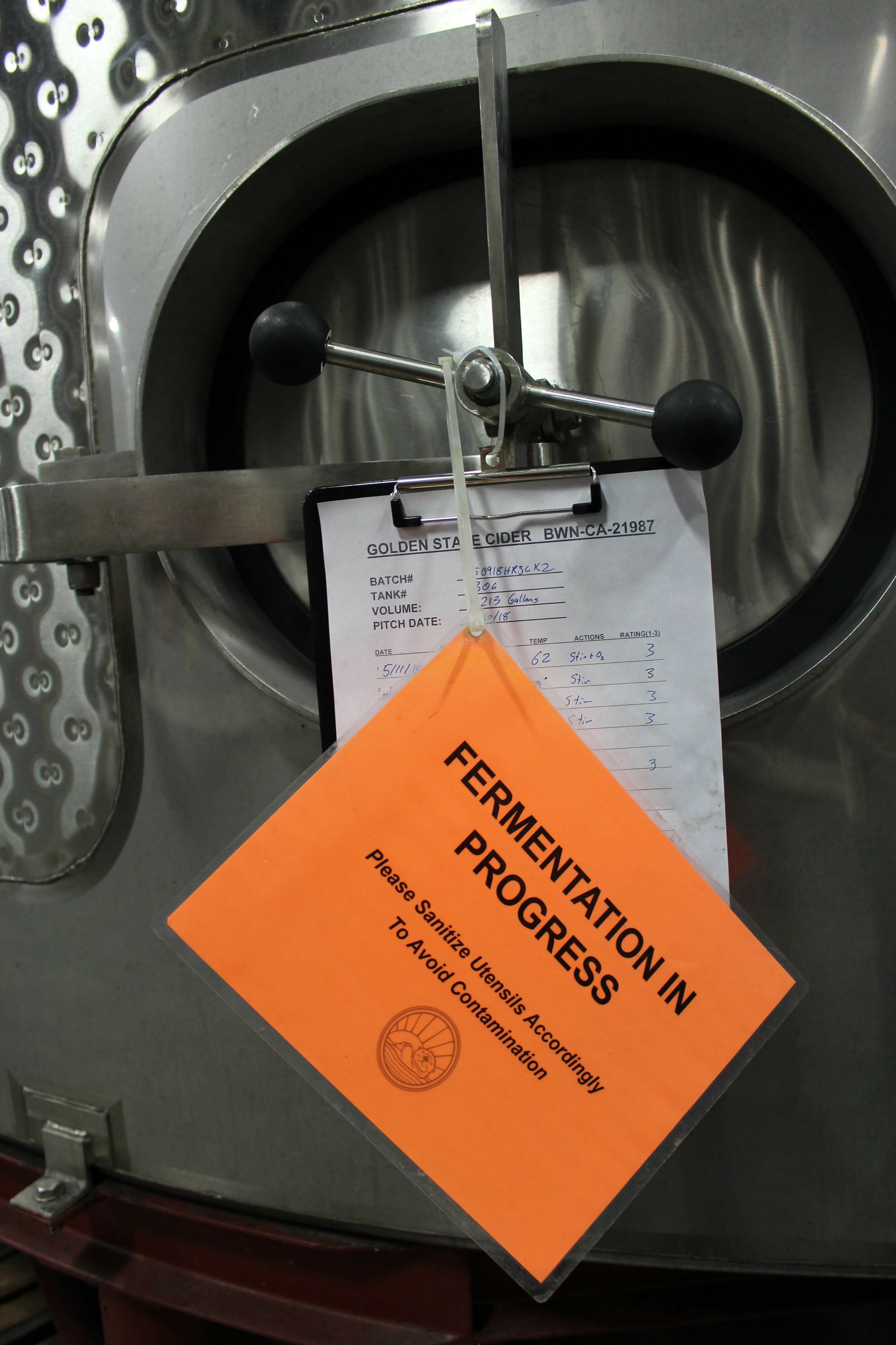

The cidery

Utilizing an old, apple processing facility on Gravenstein Highway, Golden State Cider now produces their product line – four ciders available year-round, as well as their seasonally-available harvest series. The equipment is state-of-the-art.

11,000 gallon stainless steel fermentation tanks

Their first year’s production of cider was a mere 5,000 gallons total. In 2018 they will produce upwards of 600,000 gallons of cider. Currently in production (depicted above) is their flagship Mighty Dry Cider.

All ciders are fermented with champagne yeast in stainless steel containers at cold temperatures to capture and retain the delicate nuances of each varietal and varietal blend.

In kegs, barrels and cans, oh my!

Golden State Cider (GSC) cans or kegs every day of the week. They produce approximately 700 cases of canned product per day. These pallets will be loaded onto a semi truck for distribution within California and Oregon. GSC makes their cider from apples grown in Sebastopol and Watsonville and additionally from Hood River, Oregon and Yakima, Washington. The majority of juice comes from the Pacific Northwest. The local apples are featured in GSC’s Harvest Series. The main product in the Harvest Series is still called Save The Gravenstein. It has always been Jolie and Hunter mission to raise awareness and help revitalize California’s historic apple growing regions.

Each can is 90% post-consumer recycled aluminum and printed in nearby Fairfield. The plastic four-pack carriers are 96% post-consumer recycled plastic. Hence, the entire packaging is 100% recyclable. Case trays (boxes) are made from unbleached cardboard.

This fall, Golden State Cider opens their taproom in The Barlow, a “maker marketplace” in downtown Sebastopol; once the apple-producing mecca for the West Coast. Jolie recalls as a toddler bringing apples to the old Barlow cannery with her father, Stan. Talk about coming full circle!

“Orchard To Table Fresh | California To The Core”

I loved this photo essay! Thanks, Michael!